In typical conditions a 1 inch thickness is the standard.

Refrigerant line insulation thickness.

If it was all vrv vrf manufacturer s would require 2 1 2 on the high pressure lines.

1 4 5 8 insulated copper coil line set seamless pipe tube for hvac refrigerant 1 2 white insulation ez twin set 35 long 167 99 167.

Liquid lines generally are insulated.

99 get it as soon as wed sep 30.

Mandated changes in refrigerants are resulting in colder line temperatures which require increased insulation thickness to prevent condensation.

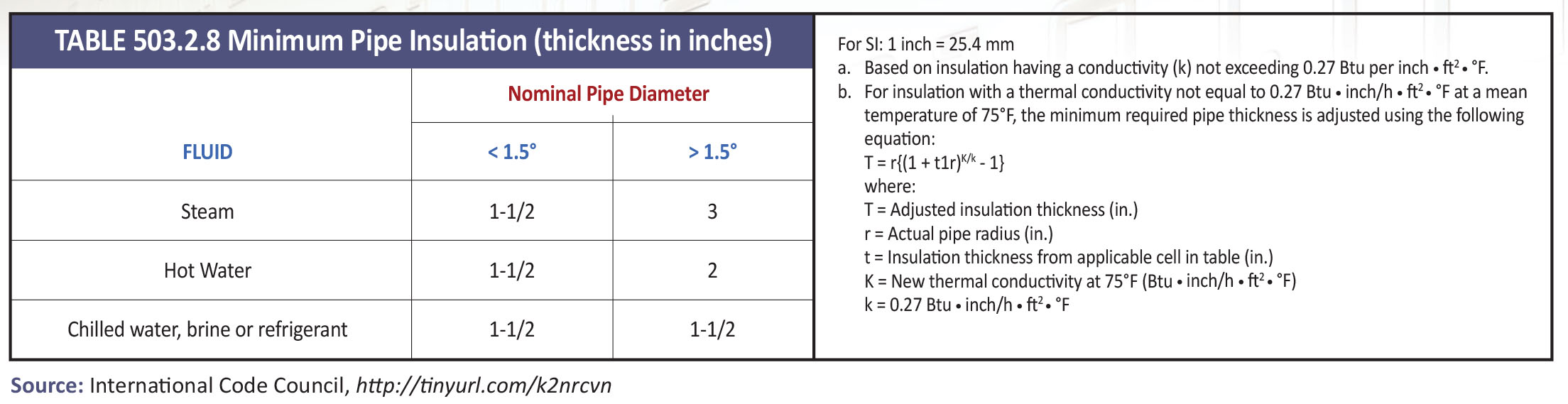

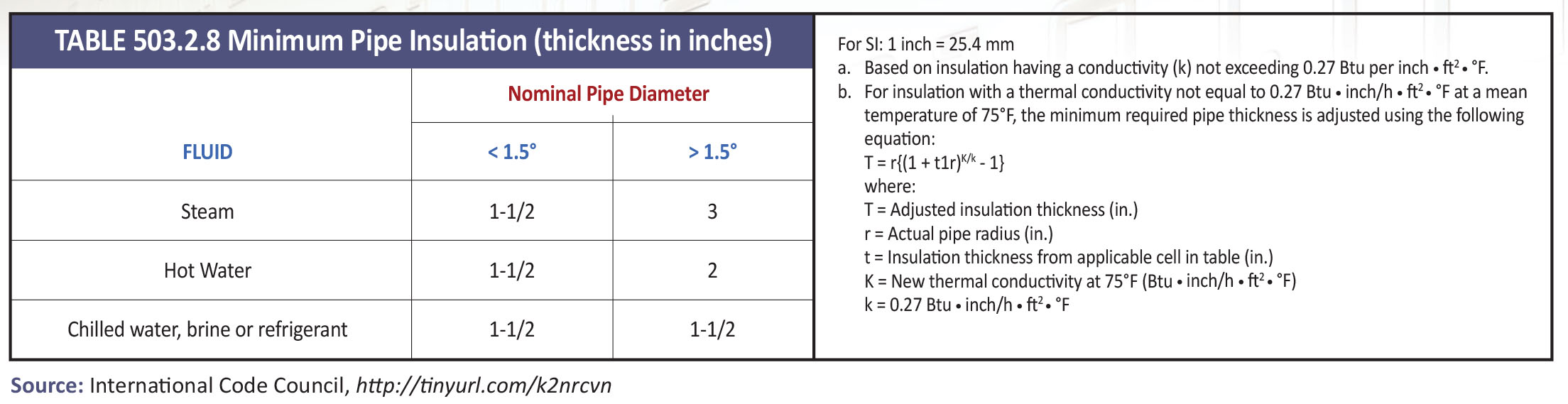

Pipe insulation thicknesses are greater than or equal to those in the 2007 standard but duct insulation thicknesses have not changed.

2 hot pipes require.

This also applies to the need for epdm on insulated coils line sets going to the fan coils.

In our photo at above left where refrigerant line insulation is incomplete the drip stains on the attic floor may well indicate a point at which leak.

This is not what dictates insulation thickness.

However in some cases where humidity is high over 80 percent a 1 inch thickness may be used.

Two different diameter copper refrigerant lines one approximately 1 4 second 3 4 diameter depends on your system size and distances run between the air conditioning system condensing unit house exterior and the ac coil a coil named after its shape.

They are warm to hot 110 f 43 3 c for air cooled.

There are two refrigeration circuits each with a liquid line supplying liquid refrigerant from the condenser to a tx valve adjacent to the evaporator and a suction line returning refrigerant gas from the evaporator to the suction connections of the compressor.

The roof of a building at roof level or if they could be considered hot enough to pose a safety risk then insulation should be added.

If liquid lines pass through a space that is warmer than the refrigerant i e.

There is a double suction riser on one of the circuits.

Missing or damaged refrigerant line insulation insulation on the refrigerant lines particularly on the larger suction line will cause condensation and drips from the lines in humid areas.

The thickness required for low temperature pipes like refrigerant and chiller water is less than higher temperature pipes and smaller pipes require less insulation as well 1 in general refrigerant suction lines and chilled water pipes require either 1 2 or 1 insulation depending on the size and temperature of the pipes.

Overall this is good news giving mechanical insulation an opportunity to contribute to greater building energy efficiency.