The focus of this paper is to investigate the system performance of standard asphalt shingles and to evaluate the impact of installing nonbreathable underlayments between the shingle layer and the roof deck.

Permability of roofing paper.

High permeability when wet.

This measurement was derived by using the astm e 96 test.

Tar paper has been time tested as a weather barrier.

It s more complicated for films and coating however and this rule should not be applied to these materials.

Necessary to protect the roof sheathing from moisture within the home.

It improves look and uniformity because your roof deck might not lie perfectly straight or flat a layer of roof paper gives an even uniform surface upon which you can install your shingles.

The water vapor permeability of a material is roughly inversely proportional to its thickness doubling the thickness halves the permeance.

Absorbs stores water.

Moderate resistance to liquid water.

Saturated and coated roll roofing 65 0 05 0 24 kraft paper and asphalt laminated reinforced 30 120 30 6 8 0 3 1 8 blanket thermal insulation back up paper asphalt coated 6 2 0 4 0 06 4 2 asphalt saturated but not coated sheathing paper 4 4 3 3 20 2 asphalt saturated and coated vapor barrier paper 8 6 0 2 0 3 0 6 15 lb asphalt felt 14 1 5 6.

The research performed indicates that nonbreathable.

This measurement was derived by using the astm e 96 test.

When and why condensation occurs inside buildings explains the problems caused by excessive indoor condensation explains how moisture enters building wall and ceiling cavities.

Table of permeability ratings for sheathing wrap products for building sheathing products.

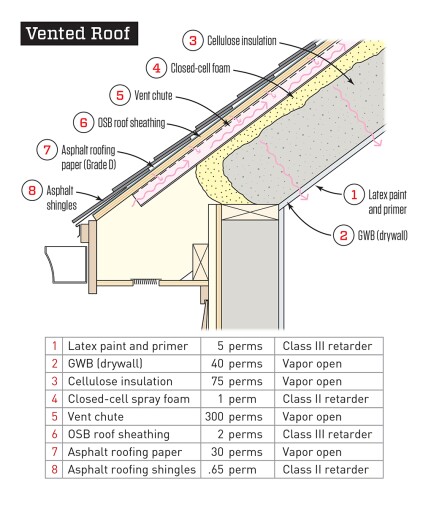

A technical white paper produced in 2011 shows that 15 felt paper has a vapor permeance rating of 7.

Asphalt felt saturated felt tar paper sheathing wrap under siding roofing.

Roofing felt prevents the deck from being exposed to the elements before or while the shingles are being applied.

Fortifiber two ply super jumbo tex.